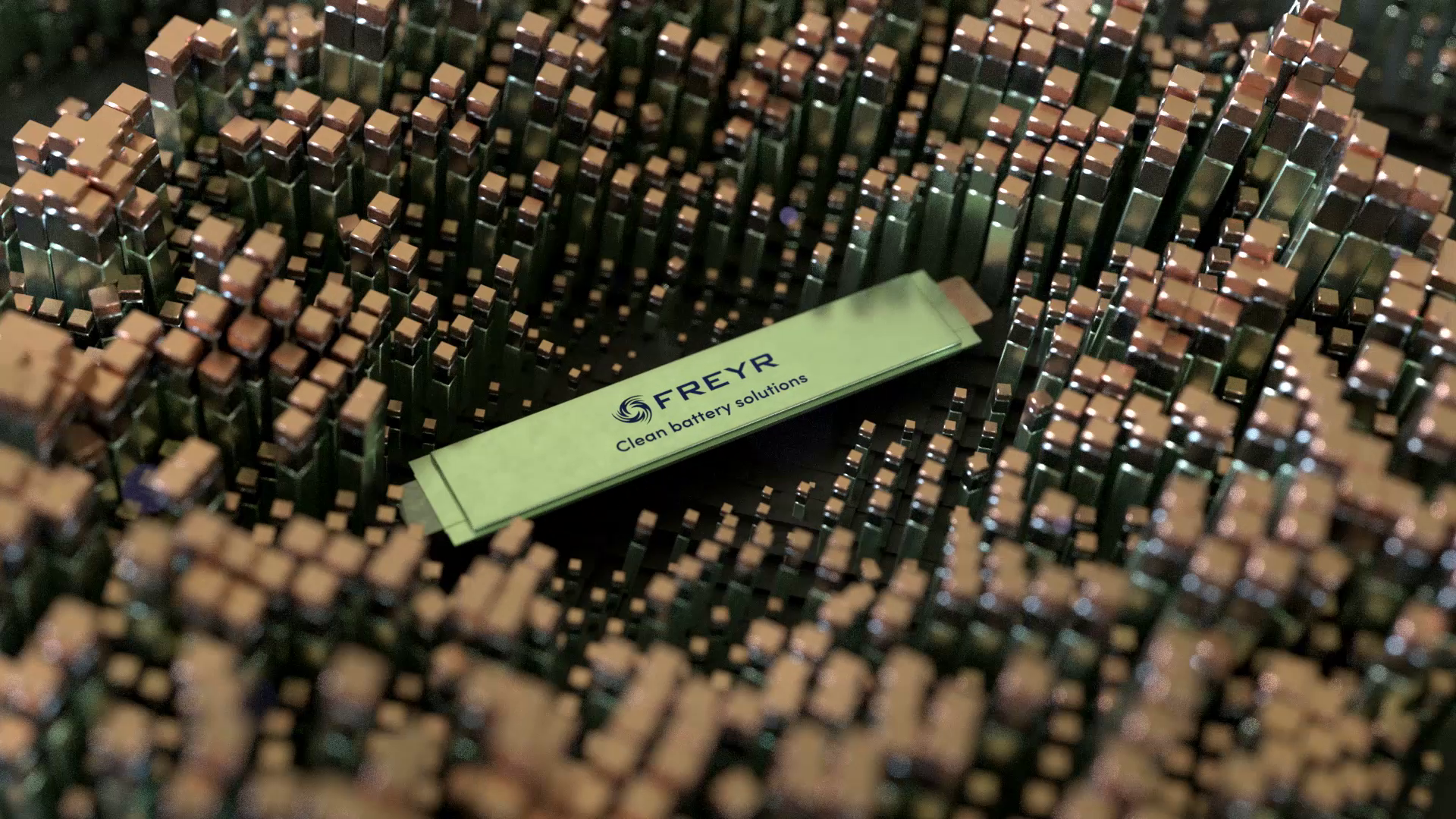

FREYR is developing environmentally friendly lithium-ion based battery cell facilities in Mo i Rana, Northern Norway. Their Customer Qualification Plant (CQP) will be done before christmas 2022 and their first GIGA factory, GIGA Arctic, is under construction.

FREYR will supply high energy density and cost competitive clean batteries to rapidly growing markets globally using best available technology and globally leading partners powered by low-cost, renewable hydro and wind power.

FREYR seeks to actively contribute to creating sustainable production materials for the lithium-ion battery industry by enabling development of production facilities for active materials in the Nordic countries based on renewable energy.

Freyr is engaging with European suppliers to develop supply agreements for active materials. European materials in general, from Nordic sites specifically, are manufactured with lower CO2 emissions than in other regions of the world.

Some materials will likely be sourced globally. FREYR will require that suppliers certify that materials are produced in a responsible manner outside conflict areas with due respect to international labour standards and the environment.

Together with different partners within supply-chain, technology, equipment, production, services and research, Freyr is seeking to create a Nordic and European battery ecosystem.

Therefore Freyr is looking for partners and companies who will support the development of the Lithium-ion battery supply chain, both upstream an downstream. Upstreams means raw materials and semi processed products – anode, catode and seperators. Downstream implies battery cells, battery packs, storage etc.