Project and timeline

SMA Mineral is planning a major industrial initiative in Mo i Rana based on new, electric production technology for lime and dolomite. At the core of the project is the use of plasma furnaces developed by the Swedish technology company SaltX. This technology replaces fossil fuels with electricity in the calcination process itself.

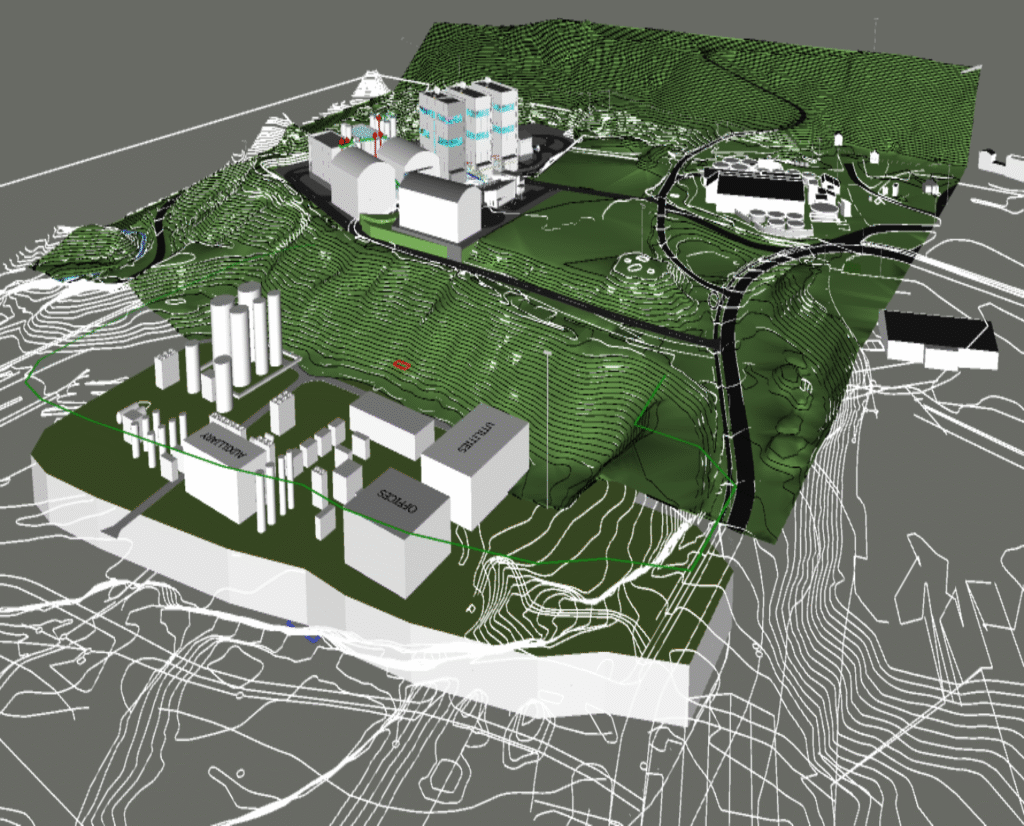

The company has decided to build a pilot plant to verify the technology at an industrial scale, the first of its kind in the world. The pilot facility is scheduled for completion in 2027, followed by a testing period through 2028. Once the technology has been fully demonstrated, the plan is to develop a full-scale plant consisting of eight plasma furnaces. This main facility is planned to be completed in 2031. The plant will have an annual capacity of 320,000 tonnes of calcined lime and dolomite, serving both existing customers and new markets.

CO₂ management and fuel production

Today’s production of calcined lime results in significant process emissions; approximately the same amount of CO₂ is generated as the amount of finished lime product. This gas must be managed in order to meet climate targets, either through storage (seabed deposition) or through utilization in new products (CCU). As viable storage solutions are not yet available, SMA Mineral has chosen to utilize the CO₂ gas as a resource.

The company has entered into a strategic partnership with the U.S.-based company Infinium. Infinium will use CO₂ from SMA Mineral’s plant, combined with hydrogen, to produce synthetic fuel, specifically e-SAF. This means that the project in Mo i Rana will not only supply essential minerals to industry, but also serve as a feedstock provider for the green transition in aviation.

The marked for calcined lime

Calcined lime is a critical input in a number of socially essential value chains:

- Smelters and the metals industry: Lime acts as a flux, lowering the melting point and removing impurities form the metal. This is particularly relevant for the process industry in Mo i Rana.

- Pulp and paper industry: Used in the chemical recovery process in kraft pulp mills (with substantial consumption in lime kilns), as well as for bleaching and as a filler in paper.

- Agriculture: Used for soil conditioning to adjust soil pH, optimizing growing conditions and nutrient uptake for plants.

About SAF og e-SAF (Sustainable Aviation Fule)

Sustainable aviation fuel, often referred to as SAF, is an alternative to fossil jet fuel that significantly reduces greenhouse gas emissions.

- SAF: Traditionally produced form biomass, waste oils or fats.

- e-SAF: A subcategory of SAF that is produced synthetically using electricity (Power-to-Liquid). By combining green hydrogen with CO₂ (SMA’s lime production generates calcined lime and a pure CO₂ gas stream), a liquid hydrocarbon is created that can be used directly in today’s aircraft engines. This is considered a highly scalable solution for the future of aviation.

Description of the companies

- SMA Mineral: leading family-owned company in lime and mineral production. It supplies products to the steel, pulp and paper industries, as well as to environmental applications and agriculture. The company has an ambitious strategy to halve its CO₂ emissions and is the developer of the new plant.

- SaltX Technology: A Swedish greentech company listed on the Stockholm Stock Exchange. It develops and supplies electrification technologies for heavy industry, including energy storage and the patented “Electric Arc Calciner” (plasma furnace), which enables emission-free heating in lime production.

- Infinium: A U.S.-based company that is a pioneer in e-fuel technology. It focuses on decarbonizing heavy transport (aviation, shipping, and trucking) by producing ultra-low-carbon fuels from CO₂ and renewable power. The company is the technology partner that will convert emissions from Mo i Rana into valuable fuel.